Front Cross Member Flip 40 Series Land Cruiser To 80 Series Chassis

The Front cross member flip is a easy job when tackled correctly Read carefully. This is how to fit Refab Engineering Front Crossmember gussets

Before cutting the front crossmember loose, Weld a section of steel across the front of the frame rails. This will ensure your chassis stays square and true.

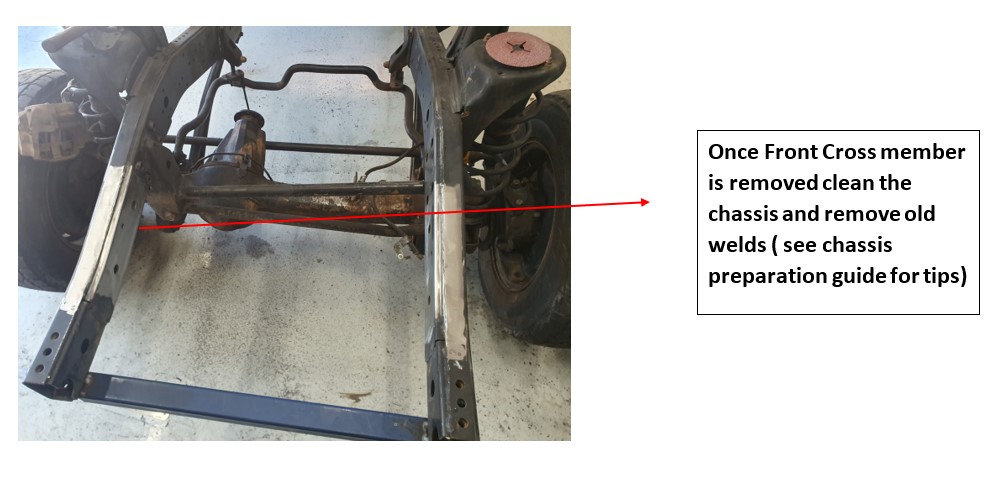

Carefully remove the factory triangle gussets by cutting right next to the weld, leaving a thin layer of material. This minimizes the risk of fighting against weld penetration. Once cut, gently use a chisel to separate and remove the remaining parts.

Once the top and bottom gussets are removed, cut the side welds. It’s important to cut as close to the weld as possible to avoid leaving too large a gap for rewelding. Use a rawhide hammer to avoid marking the steel — or alternatively, use a block of wood and a lump hammer.

If the cuts are made correctly, a few firm taps back and forth should break the piece loose. If it’s still holding, check and cut further — but be careful not to cut into the chassis rail.

Gently hammer a pry bar or chisel but don’t dent or mark chassis. if the material doesn’t crack though cut a little more but don’t cut into chassis. Once removed correctly you should be left with the factory welds.

Weld-through primer is a specialized coating used to protect metal surfaces from corrosion.

Preparation

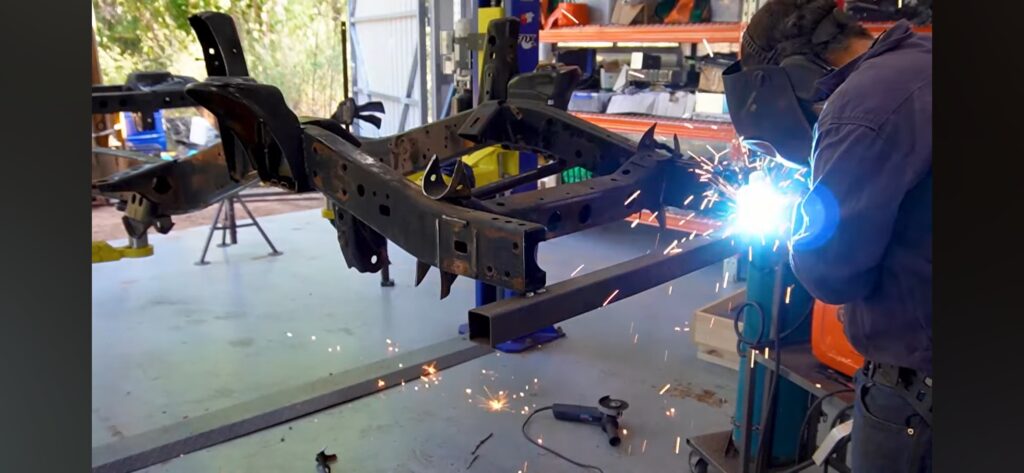

Welding

- Once the parts are tacked and prepared for welding, it’s important to clean the edges, While the design allows for welding through paint, welding on bare metal typically results in better weld quality.

This next step is important you need to add all the front grill rubbers use brand new rubbers to insure correct fitment of body panels.

Important not to forget the stainless bonnet plates all these parts will set up the correct heights.

🔩 Bolt Together: Bonnet, Front Grill, and Side Panels

Take your time during this process to ensure precise fitment — panel gaps will be clearly visible on the finished product, so attention to detail now will make a big difference in overall appearance. Use clamps to make the front end one hinged unit check all gaps with a ruler and adjust to suit.

Once happy with fitment bolt on front grill hinge if there’s a gap use rubber to insulate from having steel on steel. Only tack weld crossmember to chassis we like to do the weld out at the end of the project to make sure everything is fitting well.